Brunswick Parson Shuffleboard

Introducing the extraordinary Brunswick Billiards Parsons Shuffleboard Table! Prepare to be astounded by the flawless combination of modern design and timeless elegance. This table not only exhibits exceptional durability, but also boasts a minimalist construction and a natural dry oak finish that beautifully showcases the distinctive hardwood knots and cracks. Each piece is truly unique, adding a touch of character to any space it graces.

Description

Description

Specifications

-

SIZE 12 Ft

-

DIMENSIONS 146.5”L x 31.9”W x 32.2”H

-

LEGS Leg levelers

-

SURFACE 0.25" polymer resin surface

-

PLAYFIELD North American maple hardwood

Features

- Crafted in Brunswick’s natural dry oak finish

- Split playfield option available

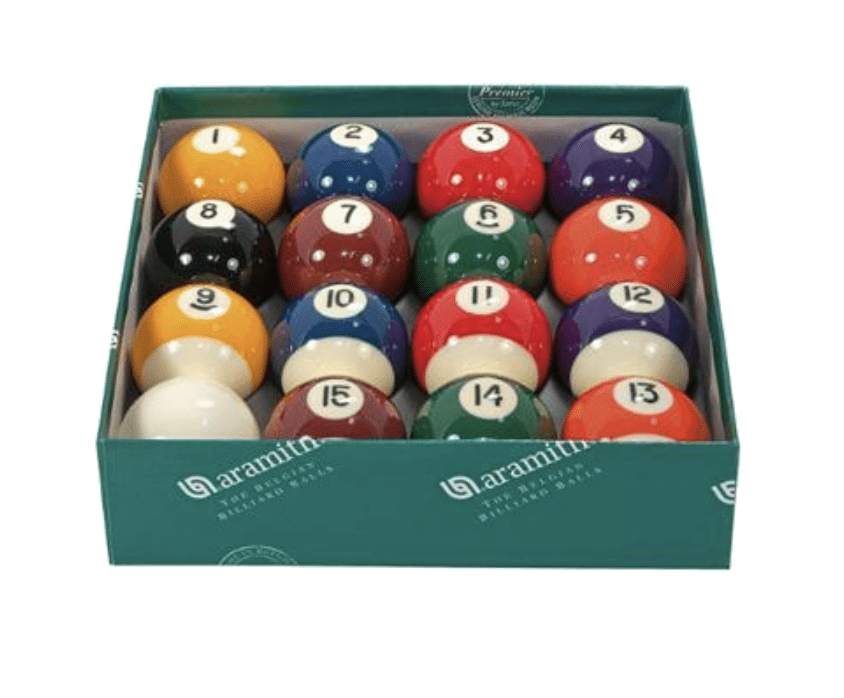

- Accessories include: four black weights, four red weights, built-in abacus scoring system, table brush, and shuffleboard wax

- Embedded Abacus scoring on each table end

- Cabinet lined with a complimentary color carpet

- Crafted in Brunswick’s natural dry oak finish

Parsons II 12' Shuffleboard Table by Brunswick

To find out more about this table, get in touch or visit our showroom

TAKE A LOOK AT OUR

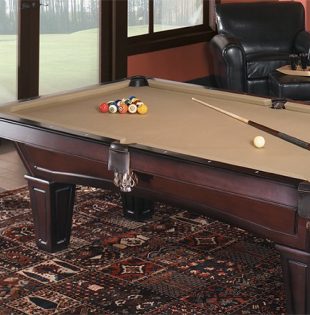

Top selling Brunswick tables

Brunswick is an iconic American Billiard Table manufacturer that has stood the test of time. With over 175 years of experience, Brunswick Tables combine classic knowledge with innovative features so you get the best accuracy and consistency to your game.

Why buy a Brunswick?

The 12 Advantages apply to most Brunswick tables. Specific table construction details can be found in the “Features” section

of each table’s product page. The 12 Advantages do not apply to CONTENDER tables.

of each table’s product page. The 12 Advantages do not apply to CONTENDER tables.

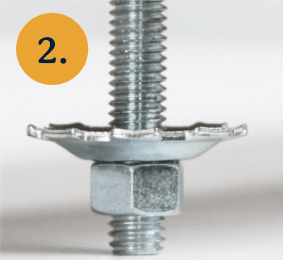

High Performance™ Nut Plates

Our exclusive nut plates allow for the application of 70% more torque to each connection, ensuring a solid, seamless transition between rail and slate that enhances performance and playability.

Hardened Dome

Washer

Our hardened dome washer ensures that the rail is gripped directly on the table, providing constant tension, which prevents turning, sinking and loosening over time.

Superspeed® Cushion Rubber

Brunswick SuperSpeed cushions have set the standard for over 70 years. The proprietary rubber formulation provides greater accuracy, control and rail consistency.

High Pressure

Bonding

Precision is critical and cushion rubber bonding and placement are essential to the overall performance. Brunswick achieves superior accuracy and consistency through proprietary pneumatically controlled machines that bond the cushion rubber to the rails for a precision fit that doesn’t vary.

Accurate Nose

Height

Banking and rebound accuracy rely on the nose height of the table’s cushion rubber. Brunswick’s automated, pneumatically controlled machines precisely place the cushion rubber ensuring consistent nose height all around the table that meets the 64% of a 2 1/4" diameter ball standard.

Solid Hardwood

Rails

Brunswick rails are made of solid hardwood. The rails are machined to exacting standards and provide a solid foundation behind the cushion rubber to ensure exceptional accuracy and performance.

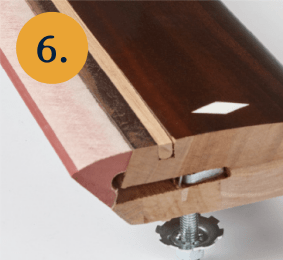

Machined Recessed

Area

Recessed areas machined into the rail allow the rail cloth to be stapled securely many times over and not interfere with the rail attachment to the slate.

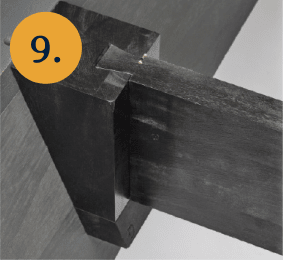

Stable Joinery

Construction

Brunswick uses fine furniture joinery techniques in the construction of all solid hardwood products. These joinery techniques create a stronger, more stable construction that provides flawless performance for years.

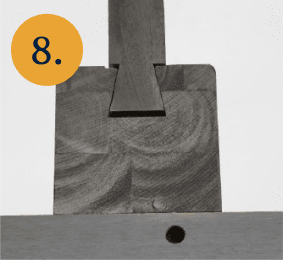

Solid Wood Dovetail Support

Solid wood cross supports utilize dovetail joinery to connect the table frame at each slate joint. This provides superior performance, supporting the slate joints as if the slate was one piece.

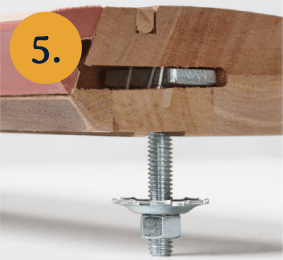

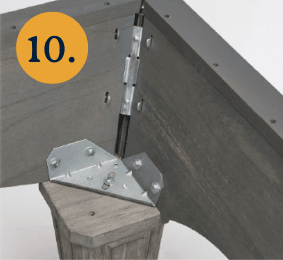

Rock-Solid and Ready to Install

Brunswick tables come ready to assemble. We utilize machine nut and bolt construction and galvanized steel leg-plates to achieve a rock solid fine furniture product that is easy to deliver and install in homes.

Kiln-Dried, Stained and Sealed

Brunswick tables are built to last a lifetime. All solid wood materials are kiln-dried to a 6-8% moisture level, then stained and sealed to keep moisture out. A durable furniture finish completes the look of each product, for a lifetime of playability.

Brunswick Certified Slate

Our slate is measured to a rigorous standard twice exceeding BCA specification. The slate is precision-machined and leveled to within ten thousandths of an inch, then checked for flatness on each side four times throughout the machining and curing process. Finally, each set is quality inspected and certified for playability.

Shipping & Returns

Shuffleboard Tables

Shuffleboard Tables